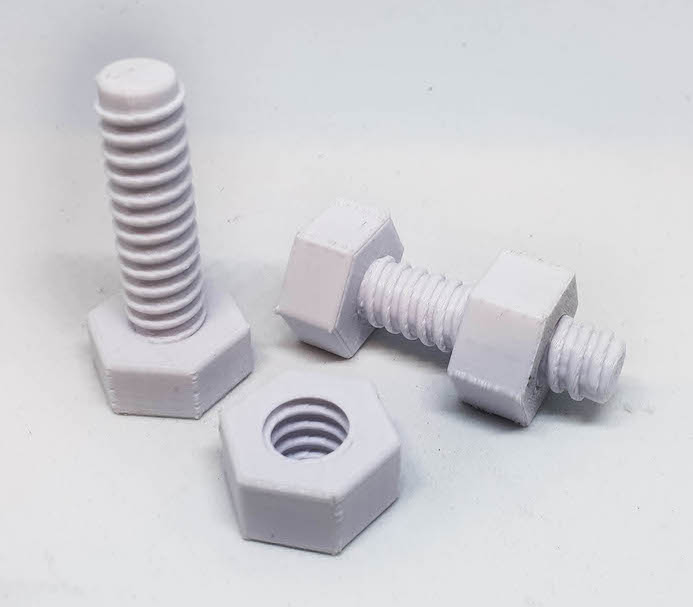

FDM Filament Printing

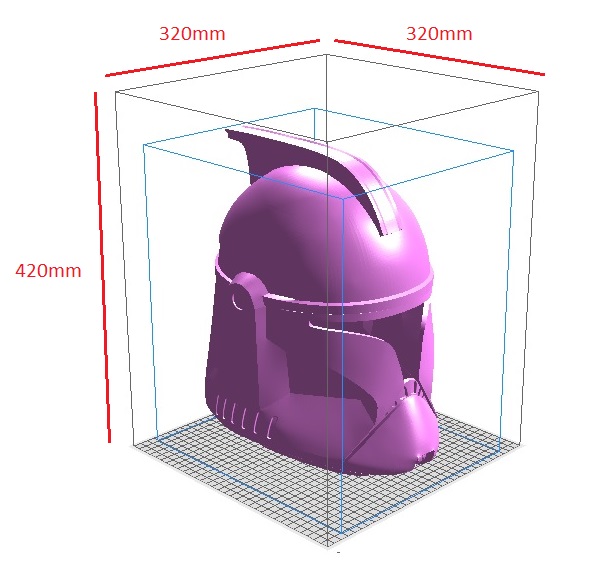

Size Guidelines: 32cm x 32cm x 42xm

Colours Available*: Black, White

*Other Colours may be available upon request.

Overview:

FDM (Fused Deposition Modelling) is a 3D printing process that is the most common and well-known form of printing. The process involves a continual flow of thermoplastic material through a heated coil. The melted plastic extrudes from the printer head and builds layer by layer of the print by precise X/Y/Z axis movements. Printing is performed with PLA plastic or ABS Plastic.

PLA vs ABS

In general, PLA has a better surface quality, but ABS is stronger.

PLA is ideal for 3D prints where the surface quality is important and where the print will not be exposed to high temperatures. ABS is ideal for 3D prints where strength and thermal resistance is required, the prints will have a reduced surface quality.

Applications:

FDM printing is ideal for large prints that are very strong for their weight. The PLA plastic is waterproof and heat resistant (PLA up to ~60 C, ABS up to ~100 C). FDM printing is ideal for proof of concept prototyping as it is more cost effective, faster and lighter. Layer heights are as small as 0.05mm.

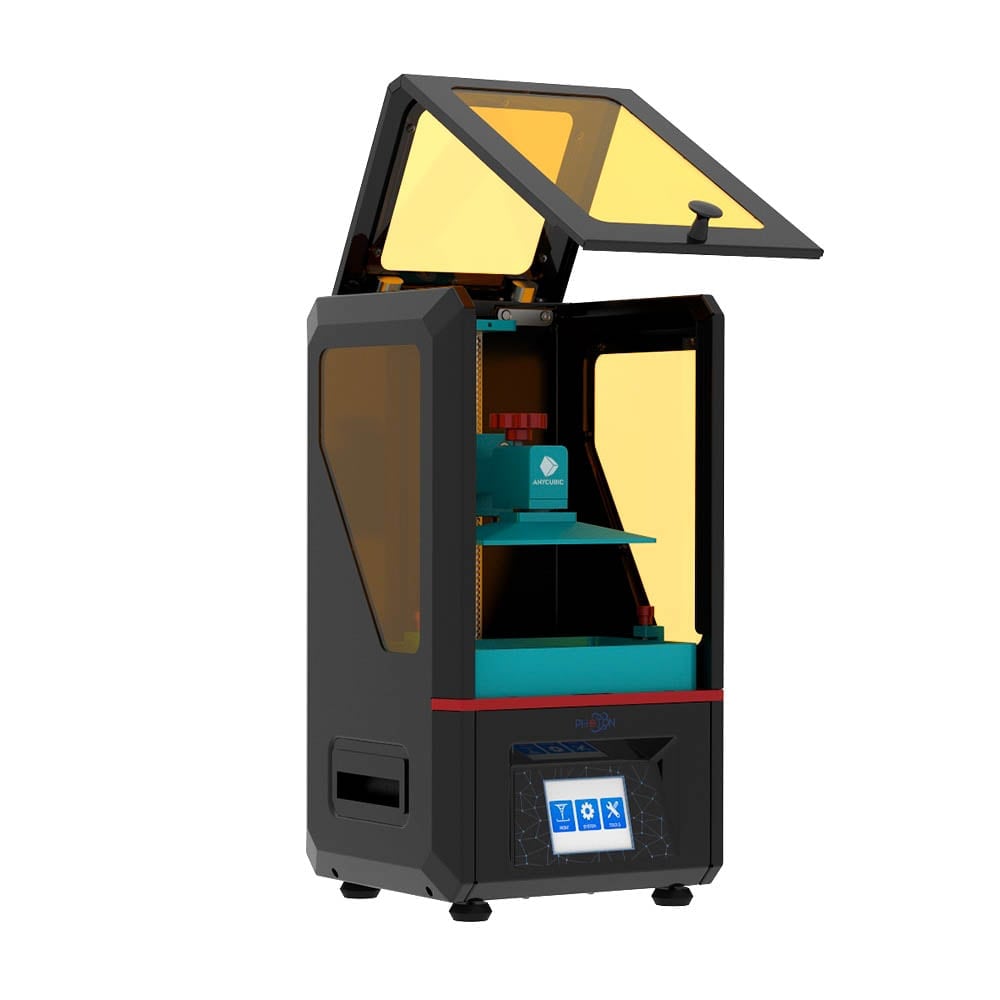

SLA Resin Printing

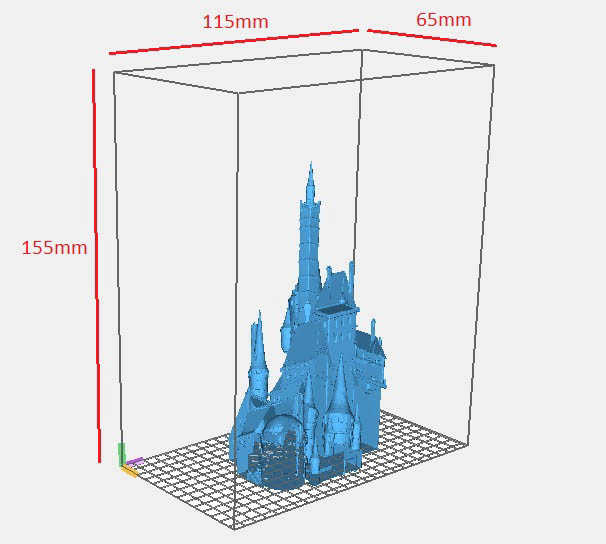

Size Guidelines: 6.5cm x 11.5cm x 15.5 cm

Colours available*: Black

*Other colours may be available on request.

Overview:

SLA (Stereolithography) is a printing process that involves UV cured resins rather than a plastic filament. These printers use a UV light source that turns the liquid resin into solid plastic resin in highly very detailed layers. The layers can be as small as 1.25 microns (0.00125 mm). Due to this tiny layer height, SLA prints have the highest resolution and accuracy, but generally take longer to print and are more expensive. SLA resin prints are strong yet brittle.

Applications:

SLA printing is ideal for small models that require a very high level of detail such as figurines, functional prototypes, moulds and detailed tools.

Comparison Guide

Size Guidelines: 32cm x 32cm x 42xm

Materials:

FDM filament printing is performed with PLA/ABS plastic. PLA/ABS are lightweight, strong and slightly flexible material. SLA resin printing is performed with liquid resins that UV cure into solid plastic. SLA resin is heavy, strong and brittle plastic.

Surface Quality:

FDM filament printing has much thicker layers than SLA printing, 0.05mm and 0.00125mm respectively. Due to this, FDM prints have characteristic ‘print lines’ on the surface of the print, these print lines can be sanded to be smooth but on a raw print they are visible. SLA prints have such a thin layer height that the surface appears completely smooth to the eye and touch. This increases the resolution of the prints and overall accuracy.

Costs:

FDM filament prints is much cheaper than SLA resin printing, in machine cost, machine maintenance and material costs.

Due to this, FDM is better for larger prints and SLA is better for smaller prints based on cost. In both FDM and SLA printing, the price is dependent size of print and material usage, therefore an obligation free quote can be provided for every case, contact us here for details (links to contact us page).

FDM Example Prices:

SLA Example Prices:

28mm Miniatures: ~$9 AUD per miniature (picture of a figure)

Full Scale Lightsaber: ~$60 AUD (unassembled/unpainted)